Duravi is committed to delivering products that meet the highest quality standards, upheld through rigorous testing protocols and certifications.

Solutions

CatalysT

01.

Duravi Catalyst is a groundbreaking solution designed to revolutionize the performance and longevity of metal components by utilizing a low energy Catalytic Alloying and Atomic Rearrangement (CAAR) process to enhance and strengthen metal surfaces.

Developed from over 39 years of research and comprising 99% plant-based ingredients, the Duravi Catalyst is both effective and environmentally friendly. It ensures that machinery operates more efficiently, lasts longer, and requires less maintenance, delivering significant cost savings and sustainability benefits.

-

Significantly decreases friction, allowing for smoother operation and extended lifespan of moving parts.

-

Transforms the molecular structure of metal surfaces, creating a smoother, harder, and more corrosion-resistant finish.

-

Withstands temperatures exceeding 2,500°F, ensuring optimal performance in high-stress environments.

-

Catalyst Applications

Solutions

PLS

02.

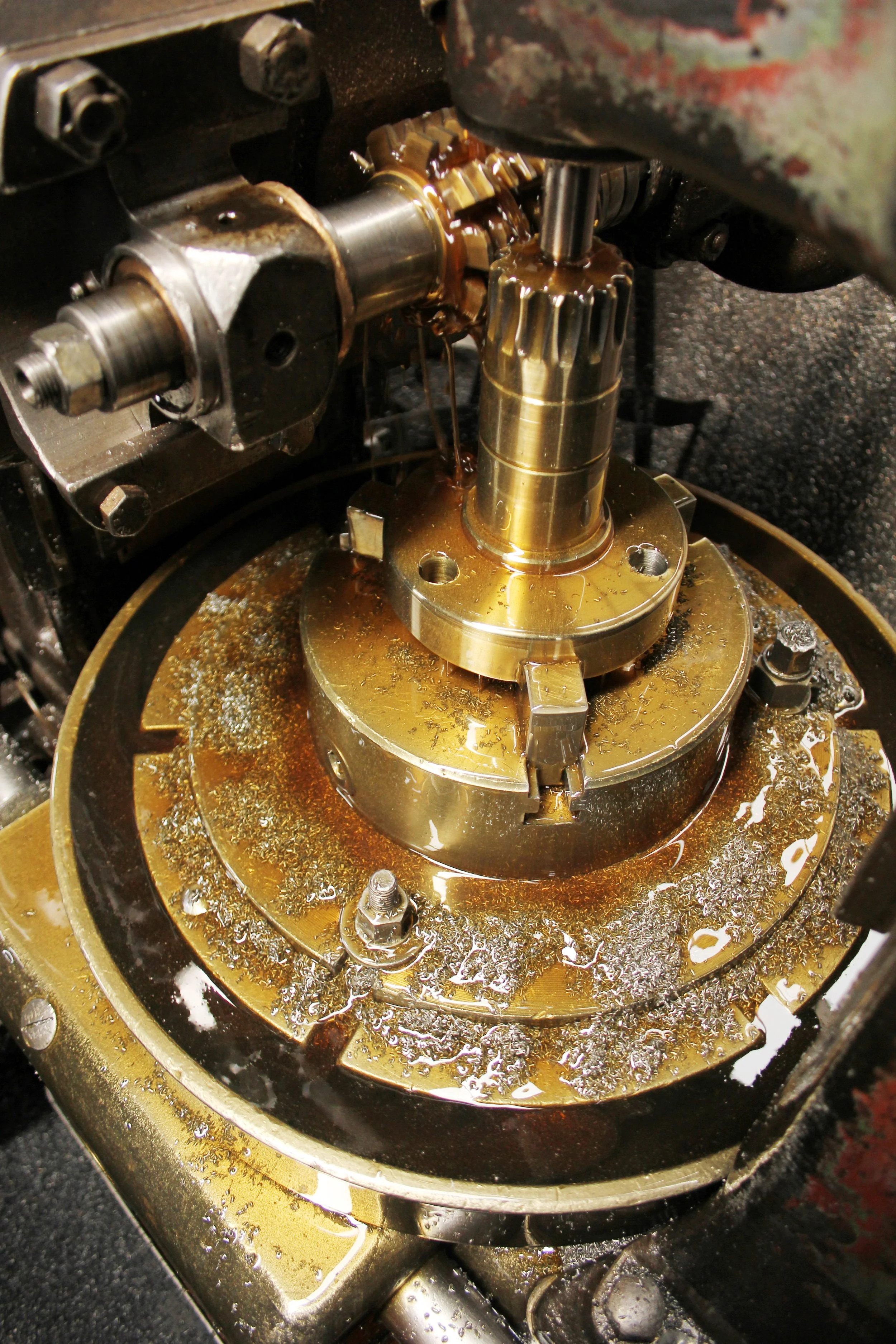

Duravi Penetrating & Lubricating Spray (PLS) is a versatile, all-in-one solution designed to tackle a wide range of maintenance challenges.

Formulated with advanced bio-based ingredients, Duravi delivers superior penetrating power, quickly loosening rusted or stuck parts while providing long-lasting lubrication to prevent future wear and corrosion.

-

Duravi PLS metal enhancement properties are ideal for protecting saws and drill bits in machine shops or sharpening knives in the kitchen. It lubricates, hardens, and conditions metal surfaces, reducing friction and wear. This results in smoother operation, extended machinery and tool life, and reduced maintenance costs.

-

Duravi's eco-friendly formulation not only safeguards your equipment but also aligns with sustainable practices, making it a responsible choice for both industrial and home use. Whether in the workshop, garage, home, or on the job site, trust Duravi to lubricate moving parts like hinges, wheels, rollers, chains, gears tools or loosen rusted, frozen or stuck parts.

-

In addition to its powerful penetrating action, Duravi offers excellent water displacement properties, effectively protecting metal surfaces from moisture and preventing rust formation. This makes it ideal for use in harsh environments where metal components are exposed to humidity or water.

-

-

PLS Applications

Solutions

ENGINE ENHANCER

03.

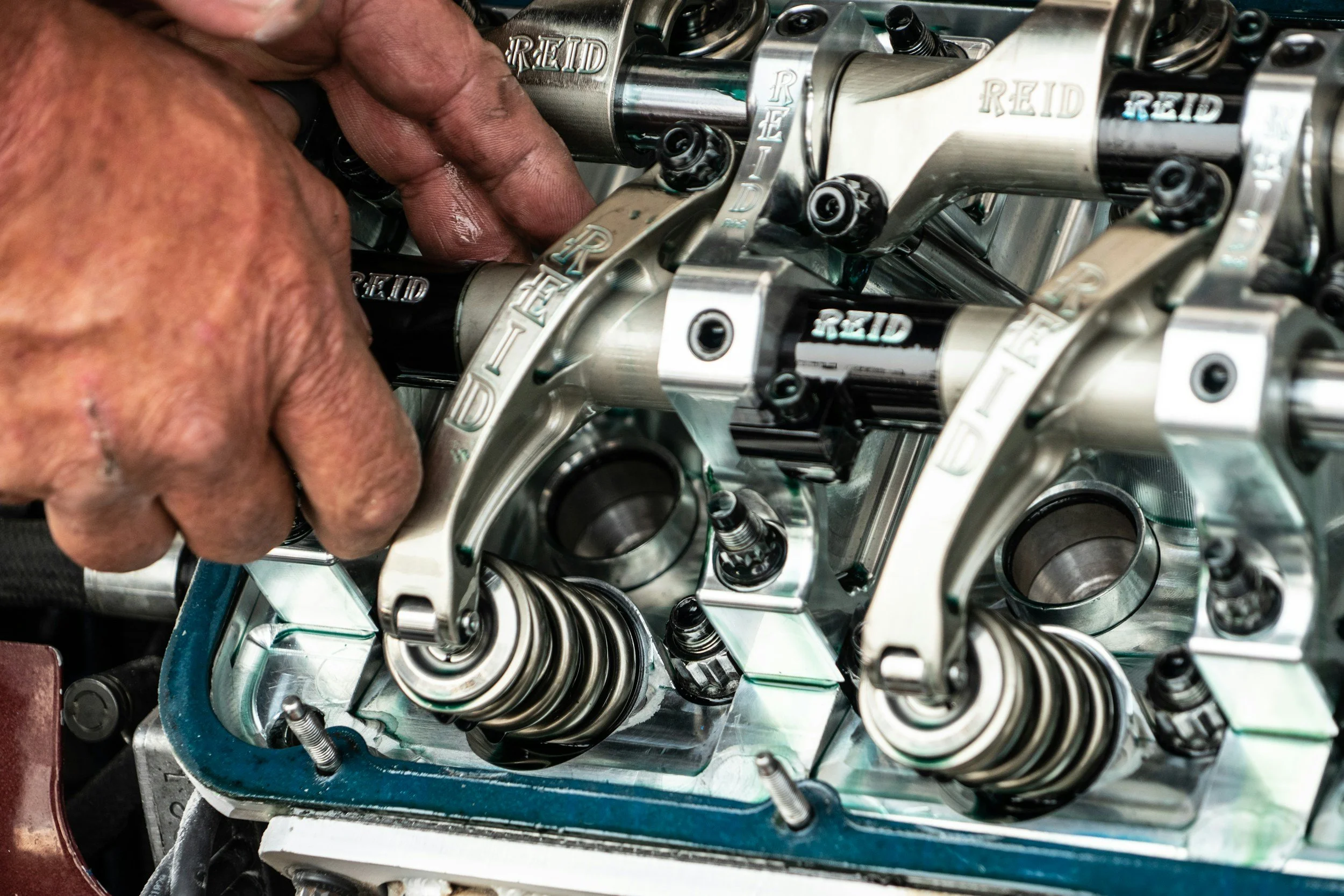

Duravi Engine Enhancer is a groundbreaking solution designed to revolutionize the performance and longevity of engines and metal components by utilizing a low energy Catalytic Alloying and Atomic Rearrangement (CAAR) process to strengthen metal surfaces.

Ideal for both commercial and personal use, Duravi Engine Enhancer is a key solution for anyone looking to optimize their engine’s operation.

-

This advanced tribological action not only reduces wear but also extends the lifespan of engines and equipment, ensuring peak performance by reducing oil consumption and “sludge” build-up, eliminating “dry start” and enhancing removal of heat to protect against catastrophic lubricant failure.

-

Increases power (by up to 4.2%) and system efficiency (by up to 7%) in new and worn equipment.

-

Helps to reduce GHG Emissions by 30 – 70%

-

-

Engine Enhancer Application

Solutions

Grease

04.

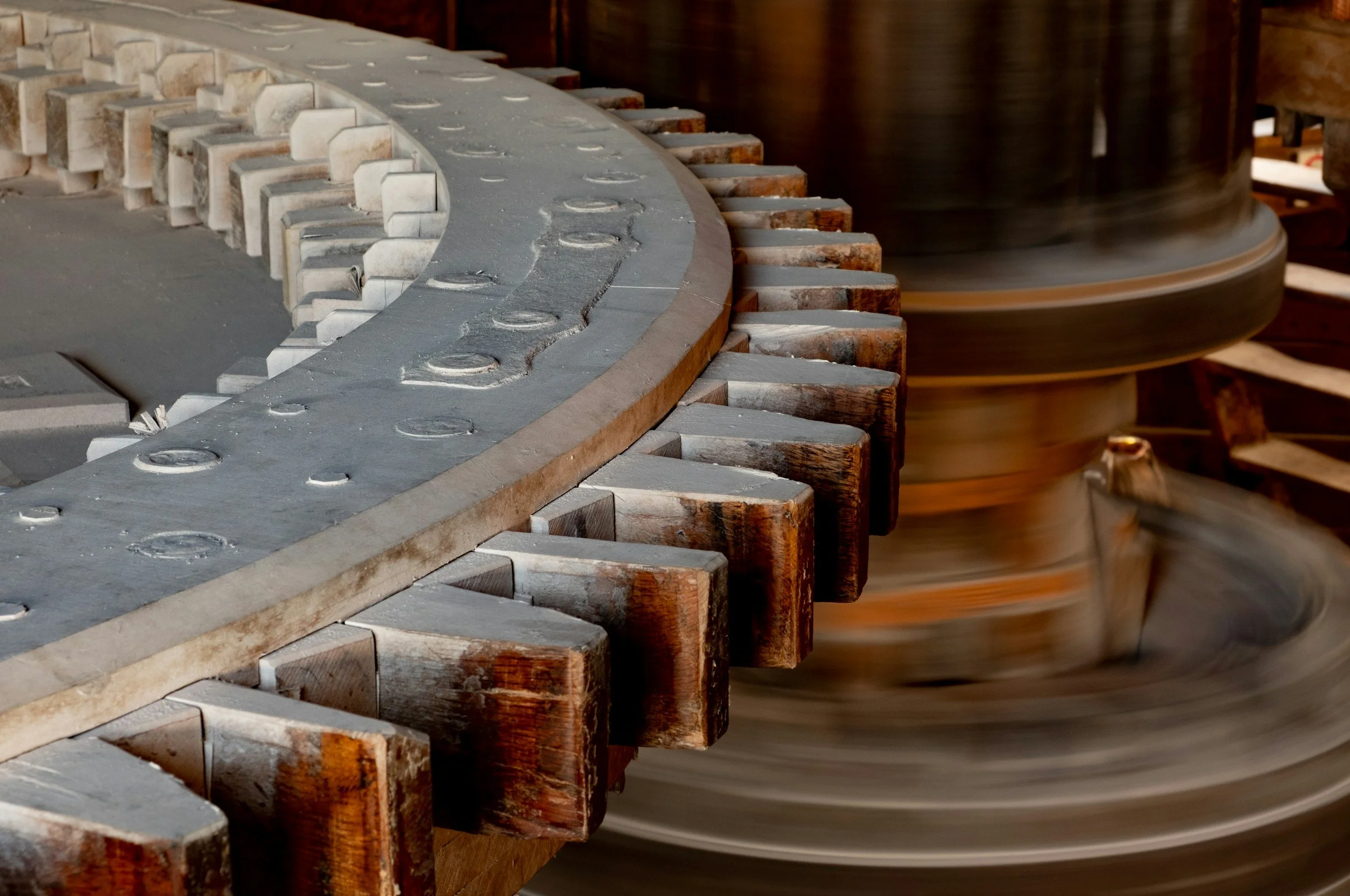

Duravi EP Grease is a high-performance lubricant engineered to meet the demands of a wide range of applications, from automotive to industrial machinery. Formulated with advanced Duravi CAAR Tech and high-quality base ingredients, Duravi ensures excellent protection against wear, friction, and corrosion, even under extreme conditions.

-

Lubricates and conditions metal surfaces, reducing friction and wear. This results in smoother operation, extended machinery life, and reduced maintenance costs.

-

Leveraging cutting-edge technology, our bio-grease significantly increases the maximum load capacity by up to 70%, enabling your machinery to perform under higher stress with outstanding reliability.

-

Duravi’s superior water resistance and adhesion ensure that it stays in place, protecting components from moisture and contaminants that can lead to rust and degradation. Our grease forms a protective barrier that shields metal surfaces from moisture and corrosive elements, prolonging the lifespan of machinery.

-

-

Grease Applications

Solutions

FUEL ENHANCER

05.

Duravi Fuel Enhancer leverages a low energy Catalytic Alloying and Atomic Rearrangement (CAAR) process that increases metal strength and durability to protect engines and enhance performance across a wide range of vehicles and machinery.

This advanced formula not only improves combustion but also helps reduce emissions and extends the life of engine components. Ideal for both commercial and personal use, Duravi Fuel Enhancer is a key solution for anyone looking to optimize their engine’s operation and environmental impact.

-

Duravi reduces wear on critical fuel system components such as high-pressure pumps and injectors by restoring and significantly enhancing the lubricity of ULSD up to EU standards. This results in extended equipment life, reduced maintenance costs, and optimized fuel efficiency.

-

This triple action protection increases power (by up to 4.2%) and fuel efficiency (by up to 7%) in new and worn equipment, prevents fuel leaks, product contamination and catastrophic tank failures ensuring the long-term reliability and safety of both diesel and gasoline engines and equipment.

-

Helps to reduce GHG Emissions by 30 – 70%

-

Fuel Enhancer Applications

FAQ’s

Get to know Duravi through some of our most frequently asked questions.

Still have more questions? Contact us to learn more or schedule a demo.

-

Duravi is a revolutionary metal treatment technology that utilizes our proprietary Catalytic Alloying and Atomic Rearrangement (CAAR) solution to enhance metal surfaces at a molecular level. This process significantly reduces friction, enhances wear resistance, strengthens the metal, and provides corrosion protection. As a result, machinery and components treated with Duravi operate more efficiently, last longer, and require less maintenance.

-

Yes, Duravi products are versatile and can be used across various industries, including automotive, industrial machinery, HVAC, aerospace, and more. Our technology is particularly effective in environments where reducing friction and extending equipment longevity are critical.

-

Duravi products are designed with sustainability in mind. Our catalyst is 99% plant-based and 100% non-toxic, making it an environmentally friendly alternative to traditional lubricants that often contain harmful chemicals. By reducing wear and extending the life of machinery, Duravi also helps decrease waste and energy consumption.

-

Duravi’s Catalytic Alloying and Atomic Rearrangement (CAAR) Solution goes further—it persistently modifies metal surfaces at the molecular level to reduce wear and enhance durability.

By applying Duravi Catalyst, a proprietary, mostly plant-based formula, a chemical reaction is triggered at friction points, causing a restructuring of the metal’s surface. This reaction forms a denser, more uniform surface.

-

Users of Duravi products have reported significant improvements in machinery efficiency and durability. For instance, in industrial applications like mining and agriculture, Duravi-treated equipment has shown up to 50% lower maintenance costs and extended operational life. Visual and vibrational evidence from treated components confirms a substantial reduction in wear and friction.

-

Equipment treated with Duravi can be outfitted with monitoring systems that track performance metrics such as vibration levels, temperature, fuel/energy consumption, and wear. These systems provide real-time data, allowing users to observe the ongoing benefits of Duravi’s Catalytic Alloying and Atomic Rearrangement (CAAR) process and ensure that the equipment maintains optimal performance throughout its lifespan.

-

Duravi has been proven to impact a company’s bottom line by decreasing energy use, lowering emissions, reducing obsolescence and CapEx, minimizing downtime and reducing maintenance cost.